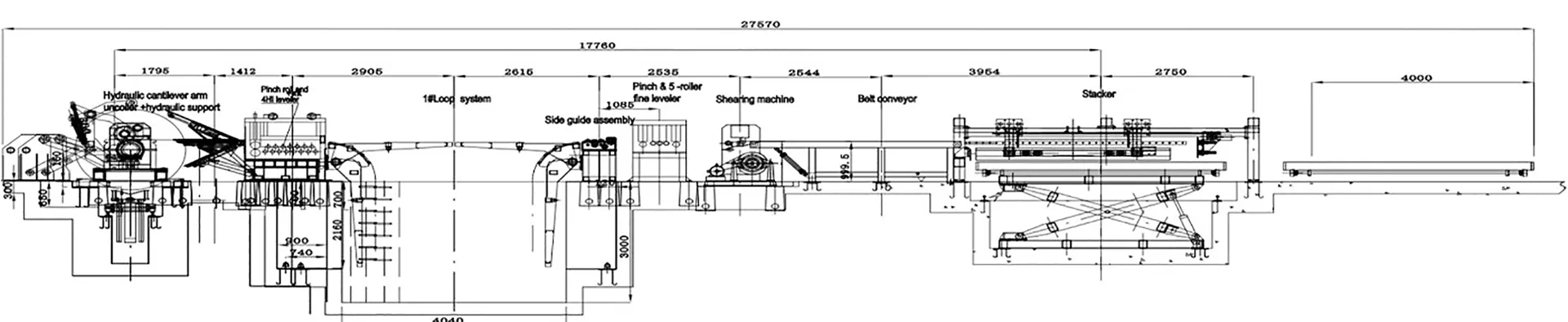

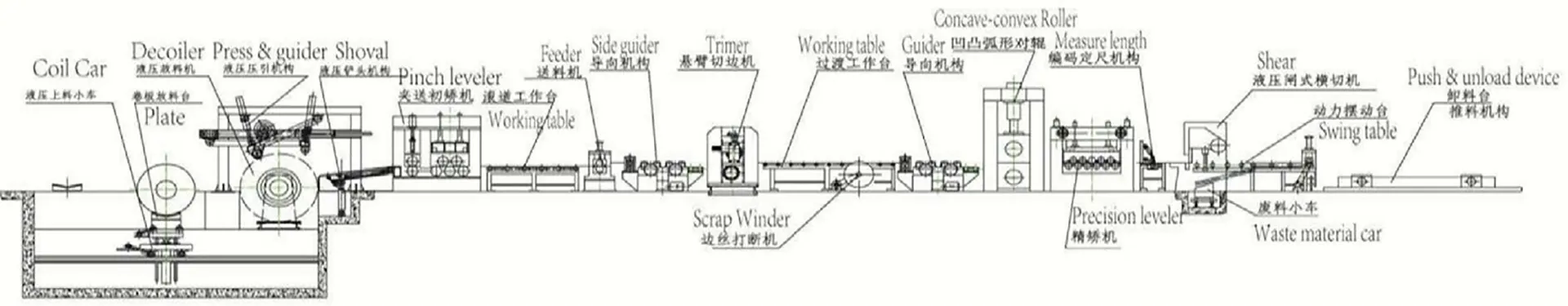

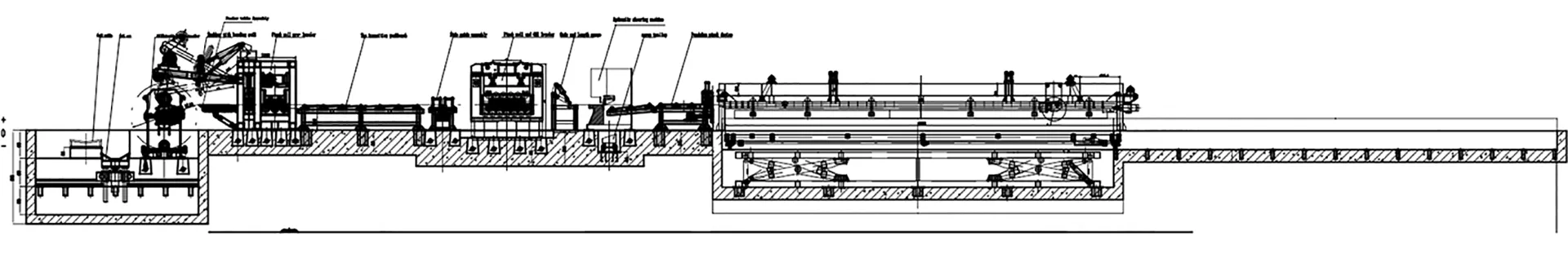

The cut-to-length machine is used for uncoiling, leveling, sizing, cutting the metal coil into the required length of flat sheet, and stacking. It is suitable for processing cold rolled and hot rolled carbon steel, silicon steel, tinplate, stainless steel, and all kinds of metal materials after surface coating.

The advantage

- Feature the best“real world”cut to length tolerances in the industry regardless of material width or thickness

- Can process surface critical material without marking

- Produce higher line speeds without experiencing material slippage

- Incorporate“hands free”material threading from Uncoiler to Stacker

- Include a Shear mounted Stacking System that produces perfectly square stacks of material

- Are designed,manufactured,and assembled in their entirety in our plant.Unlike other Strip rocessing Equipment manufacturers,we are not simply a company that assembles theinished components.

UNCOILER

Capacity is from 10ton to 25 Ton.the steel coil with diameter 508mm/610mm/760mm can be loaded,

Single mandrel type and double mandrel type are available at option.

The mandrel is expanded and collapsed by hydraulic,Traversing type is available at option,

The mandrel is driven automatically by DC motor or AC inverter motor.

PINCHING ROLLER AND LEVELING MACHINE

It has pinching roller to pull steel sheet from uncoiler, the leveling roller flatten the steel sheet, the backup rollers are provided; It helps to avoid work roll deflection in shape correcting feature 4HI 19-roller and 6HI 15-roller leveling machine are available at option

4 HI19-roller leveling machine

4 HI19-roller leveling machine

6HI 15-roller leveling machine

SIDE GUIDE DEVICE, 5-ROLLER LEVELE

Guide the steel sheet in to leveler prevent the sheet from deviation, and measure and set the length by NC for high precision.

Side guide device and 5-roller leveler

NC&CODED LENGTH DEVICE

The NC length gauge and coded length gauge are available at option

SHEARING MACHINE

The stationary shearing machine and rotary shearing machine can be provided.

Stationary shearing machine

BELT CONVEYOR

Convey the steel sheet after cutting to the stacking station

STACKING DEVICE

Stacker is a device which receives cut blanks sheets, the steel sheet bundle is then transported by 2 unloading cars for further processing.

2 stackers are available at option, which work with meet high speed cut to length.

LIGHT GAUGE CUT-TO -LENGTH

|

ITEM

|

TECHNICAL INFORMATION

|

|

Model

|

CT(0.11-1.2)X1300mm

|

CT(0.2-2.0)X1600mm

|

CT(0.3-3.0)X1800mm

|

CT(0.5-4.0)X1800mm

|

|

Sheet Thickness Range(mm)

|

0.11-1.2

|

0.2-2.0

|

0.3-3.0

|

0.5-4.0

|

|

Sheet width Range(mm)

|

200-1300

|

200-1600

|

300-1550&1800

|

300-1600&1800

|

|

Linear Speed(m/min)

|

0-60

|

0-60

|

0-60

|

0-60

|

|

Cutting length Range(mm)

|

300-4000

|

300-4000

|

300-4000

|

300-6000

|

|

Stacking Range(mm)

|

300-4000

|

300-4000

|

300-6000

|

300-6000

|

|

Cutting Length Precision(mm)

|

±0.3

|

±0.3

|

±0.5

|

±0.5

|

|

Coil Weight(Ton)

|

10&15T

|

15&20T

|

20&25T

|

20&25

|

|

Leveling Diameter(mm)

|

65(50)

|

65(50)

|

85(65)

|

100(80)

|

MIDDLE GAUGE CUT-TO -LENGTH

MIDDLE GAUGE CUT-TO -LENGTH

|

ITEM

|

TECHNICAL INFORMATION

|

|

Model

|

CT(1-6)×2000mm

|

CT(2-8)×2000mm

|

CT(2-10)×2200mm

|

|

Thickness Range (mm)

|

1-6

|

2-8

|

2-10

|

|

Width Range(mm)

|

2000

|

2000

|

2200

|

|

Cutting Length(mm)

|

500-6000

|

600-8000

|

600-10000

|

|

Cutting Precision(mm)

|

±0.5

|

±1

|

±1

|

|

Roller Numbers

|

15

|

13

|

13

|

|

Roller Diameter(mm)

|

Φ140

|

Φ155

|

Φ160

|

HEAVE GAUGE CUT-TO -LENGTH

|

Model

|

CT(3-12)×2200mm

|

CT(4-16)×2200mm

|

CT(6-20)×2500mm

|

CT(8-25)×2500mm

|

|

Thickness Range (mm)

|

3-12

|

4-16

|

1-20

|

8-25

|

|

Width Range(mm)

|

2200

|

2200

|

2500

|

2500

|

|

Cutting Length(mm)

|

800-12000

|

800-12000

|

800-12000

|

800-12000

|

|

Cutting Precision(mm)

|

±1

|

±1

|

±1

|

±1

|

|

Roller Numbers

|

11

|

11

|

9

|

|

|

Roller Diameter(mm)

|

Φ180

|

Φ200

|

φ230

|

Φ260

|