As the premier welded tube mill manufacturer, SANSO MACHINERY prides itself on standing behind the equipment it produces. Consequently, SANSO MACHINERY must be much more than a design company that simply assembles equipment. To the contrary, we are a manufacturer in every sense of the word. Short of purchased parts such as bearings, air/hydraulic cylinders,motor&reducer and electrical components, SANSO MACHINERY manufactures approximately 90% of all the parts, assemblies, and machines that leave its door. From stand to machining, we do it all.

For this transformation of raw materials to cutting-edge first class equipment to occur, we have strategically invested in equipment that gives us the ability to produce quality parts and yet flexible enough to meet the requirements of our design team and preferences of our customers. Our almost 9500square meter state-of-the-art facility is comprised of 29 CNC vertical machining centers ,6CNC horizontal machining centers,4 large- size floor type boring machine,2 CNC milling machine.21 CNC gear hobbing machines and 3 CNC gear milling machines. 4 Laser cutting machines etc.

As the manufacturing environment has trended toward customization from standardization, it has been a focal point for SANSO machinery to be able to handle any challenge thrown its way.

Regardless of what is being made, today it’s a common practice to job out or outsource the manufacturing of products to other companies in China. Consequently, one might say that the production of our own parts does not align with industry norms. However,SANSO machinery feels that it gains a distinct advantage over our competition because of our in-house production capabilities. Producing parts in-house results in shorter lead times, which in turn allows us to service our customers more quickly than anyone else in the industry.

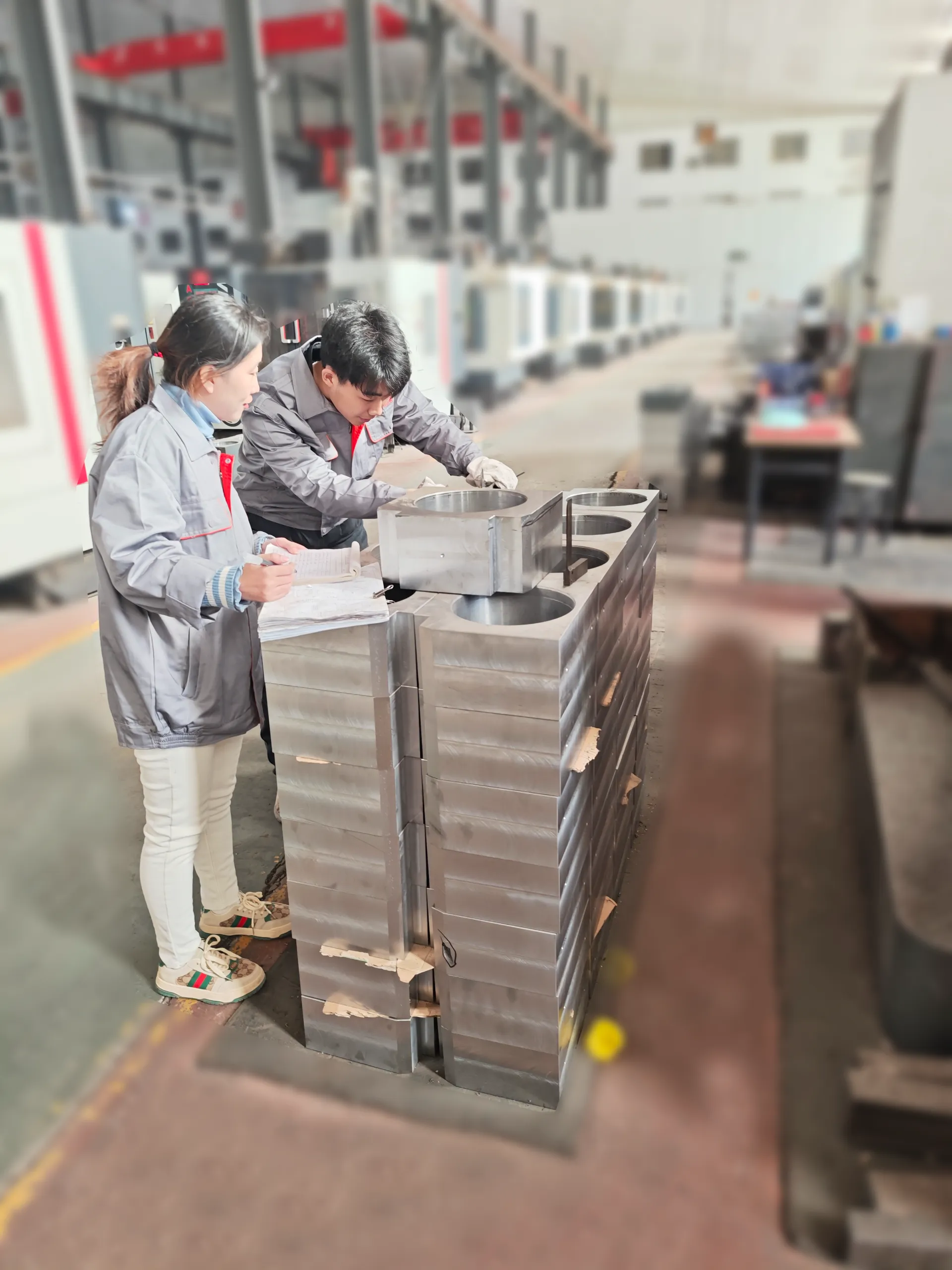

SANSO machinery is also able to maintain tighter control of quality, which has led to less manufacturing errors and higher levels of accuracy and repeatability. With our advanced manufacturing capabilities, we are also confident that our production capabilities can match our designs. In addition, it allows design improvements to be put in place instantaneously. Our manufacturing and design experience, along with advanced 3D modeling and drafting software, allows us to analyze functionality of each part and make any improvements as needed. Rather than wasting time communicating these changes to a sub-contractor, our upgrades happen in the time it takes our drafting department to deliver new prints to the shop floor. As good as our equipment and capabilities are, our greatest asset is our people.

Our model of manufacturing may be unconventional, but we feel that it is the best way to create the most value for our customers. From mind to metal, we oversee every step of the manufacturing process. In addition, we fulfill the cold commissioning of some equipment before leaving our facility. This assures the fastest and least costly installations in the industry. When you purchase SANSO machinery’s welded tube mill, you are guaranteed to receive a product that has been made with great pride every step of the way.

CNC Cutting Machine is to use digital program to drive the machine tool movement, which is equipped with flame cutting system, The CNC system to control the switch of flame cutting system to cut the steel plate. We cut the steel plate for the base of forming and sizing and vertical roller stand with the CNC cutting machine.

31 sets of CNC vertical machining center and 6 sets of CNC horizontal machining center have been in use. Which provide the unparalleled productivity and high accuracy of work piece ,thank to their automatic tool change function and receiving precise instructions from a computer.

3 sets CNC boring machine are used , they are known for their versatility and high precision,They can perform various operations, such as drilling, milling, tapping, and contouring, on a variety of large size work pieces.This means SANSO can complete more work in less time, leading to increased output and reduced lead times.

8set of CNC gear hobbling machine,8 set of CNC gear shaping machine and 3 set of CNC gear form grinding machine ,allows for extremely accurate gear production with tight tolerances. It can create complex gear tooth profiles ,they create a wide range of gear types, including spur gears, helical gears, bevel gears etc.

2 set of heavy duty CNC gantry milling machine have been operating. they offer unparalleled advantages in terms of precision, productivity, and adaptability. So the base of forming and sizing machine and large-size stands are not only machined ,but their high accuracy and high productivity can be assured.

13 set of CNC lathe have been operating . the CNC lathes are widely used for processing the various shaft and circular work pieces such as bearing sleeve or work pieces with circular shape such as bearing block

SANSO can count on an experienced professional team with over 20 years experience

Technical capacity, experience and creativity, continuous experimentation and complete knowledge of the production requirements help us to supply our clients with unique made-to-order solutions and also have created maximum value for customer from home and abroad .

Each designer is a comprehensive and comprehensive talent. They not only have rich experience in design, but also have the ability and experience of installation and commissioning at customer site, so they can design the tube mill that can best meet the needs of customers.

SANSO can count on an experienced professional team with over 20 years experience

Technical capacity, experience and creativity, continuous experimentation and complete knowledge of the production requirements help us to supply our clients with unique made-to-order solutions and also have created maximum value for customer from home and abroad .

Each designer is a comprehensive and comprehensive talent. They not only have rich experience in design, but also have the ability and experience of installation and commissioning at customer site, so they can design the tube mill that can best meet the needs of customers.